What is the specific gravity of Kaolin BRITEX-107?

The specific gravity of Kaolin BRITEX - 107 can vary depending on several factors.The

specific gravity of Kaolin BRITEX - 107 depends on a number of factors. Generally, kaolin has a

specific gravity in the range of approximately 2.58 - 2.63.Kaolin's specific gravity is typically

between 2.58 and 2.63. However, for the specific Kaolin BRITEX - 107, detailed and accurate specific

gravity data would typically be provided by the manufacturer.The manufacturer will typically provide

detailed and accurate specific gravities for Kaolin BRITEX - 107.

Specific gravity is the ratio of the density of a substance to the density of a reference substance,

usually water at 4 degrees Celsius.Specific gravity is the ratio between the density of an object

and the density (usually water at 4 degrees Celsius) of a reference material. For kaolin, its

specific gravity is influenced by its mineralogical composition.The composition of kaolin's minerals

can affect its specific gravity. Kaolin is mainly composed of the mineral kaolinite, along with

possible impurities such as quartz, mica, and feldspar.Kaolin is composed primarily of the mineral

kaolinite along with possible impurities like quartz, mica, or feldspar. The presence and proportion

of these additional minerals can change the overall density and thus the specific gravity.The

proportion and presence of these additional minerals may alter the density and specific gravity.

If the Kaolin BRITEX - 107 has a relatively high purity of kaolinite, its specific gravity is likely

to be closer to the typical value for pure kaolinite.If the Kaolin BrITEX 107 is relatively pure,

its specific gravity will be closer to that of pure kaolinite. But if it contains a significant

amount of heavier impurities like some iron - bearing minerals, the specific gravity may increase.If

it contains heavier impurities, such as iron-bearing minerals, then the specific gravity can

increase. On the other hand, if there are more lightweight impurities or a higher porosity in the

kaolin structure, the specific gravity could be lower.If there are more light-weight impurities in

the kaolin or if the porosity is higher, the specific gravity may be lower.

To determine the exact specific gravity of Kaolin BRITEX - 107, laboratory tests are

required.Laboratory tests are needed to determine the exact specific gravities of Kaolin BRITEX 107.

One common method is the pycnometer method.The pycnometer is a common method. In this method, a

known mass of the kaolin sample is placed in a pycnometer, which is then filled with a liquid of

known density.In this method, the kaolin is placed into a pycnometer and then filled with liquid of

known density. By measuring the volume of the liquid displaced and the mass of the sample, the

density of the kaolin can be calculated, and from there, the specific gravity relative to water.The

density of kaolin and its specific gravity can be calculated by measuring the volume of liquid

displaced in conjunction with the mass of sample.

Another factor that can affect the measured specific gravity is the particle size distribution of

the kaolin.The particle size distribution can also affect the measured specific gravity. Finer -

grained kaolin may pack more densely, potentially resulting in a slightly higher measured specific

gravity compared to a coarser - grained sample.Finer-grained kaolin can pack more densely and result

in a slightly higher specific gravity than a coarser-grained sample. Additionally, the moisture

content of the kaolin can also play a role.The moisture content of kaolin may also be a factor. If

the kaolin is not completely dry, the additional water mass will increase the overall mass of the

sample during density measurements, leading to an inaccurate specific gravity determination.If the

kaolin sample is not completely dried, the water mass will increase during density measurements and

lead to an inaccurate determination of specific gravity. So, samples should be properly dried before

conducting specific gravity tests.Samples should be dried properly before performing specific

gravity tests.

In conclusion, while a general range for kaolin's specific gravity exists, to know the precise

specific gravity of Kaolin BRITEX - 107, it is best to refer to the manufacturer's data or conduct

accurate laboratory tests under proper conditions.While there is a range of specific gravity for

kaolin, to determine the exact specific gravity, it's best to consult the manufacturer's data, or

perform accurate laboratory tests in the proper conditions.

What is the particle size distribution of Kaolin BRITEX-107?

The particle size distribution of Kaolin BRITEX - 107 can vary depending on several

factors.The particle size distribution for Kaolin BRITEX 107 can be affected by several factors.

Generally, kaolin is a fine - grained clay mineral.Kaolin is a fine-grained clay mineral.

In the case of BRITEX - 107, it is often processed to achieve a specific particle size range

suitable for its intended applications.In the case BRITEX - 107 it is often processed in order to

achieve a certain particle size range that is suitable for its intended application. For many kaolin

products, a significant portion of the particles are in the sub - micron to a few microns size

range.In many kaolin products a large portion of the particles is in the sub-micron to few microns

range. This is because finer particle sizes can offer advantages such as better whiteness, higher

surface area, and improved rheological properties.Finer particle sizes offer benefits such as

improved whiteness, increased surface area, and better rheological characteristics.

Typically, a substantial percentage of the Kaolin BRITEX - 107 particles might fall within the range

of 0.5 to 5 microns.A large percentage of Kaolin BRITEX-107 particles may fall between 0.5 and 5

microns. A well - processed sample may have a relatively narrow particle size distribution, with

perhaps around 80 - 90% of the particles concentrated in this key size interval.A well-processed

sample may have a narrow particle size distribution with 80-90% of the particles concentrated within

this key size range. This narrow distribution is beneficial as it allows for more consistent

performance in various industrial processes.This narrow distribution allows for more consistent

performance across various industrial processes.

For applications like papermaking, where kaolin is used as a coating pigment, a fine and well -

defined particle size distribution is crucial.A fine and well-defined particle size distribution is

essential for applications such as papermaking where kaolin is used to coat pigments. Smaller

particles in the 0.5 - 2 micron range can contribute to a smoother paper surface, enhancing

printability.Smaller particles, in the 0.5 to 2 micron range, can contribute to a smoother surface

on paper and improve printability. In the paint industry, the particle size distribution of Kaolin

BRITEX - 107 can affect the hiding power and gloss of the paint.In the paint industry the particle

size distribution can affect the gloss and hiding power of the paint. Finer particles can help in

achieving better dispersion and a more uniform film formation.Finer particles will help to achieve a

better dispersion, and a uniform film formation.

However, the exact particle size distribution can also be adjusted during processing through

techniques such as milling, classification, and sedimentation.During processing, however, the exact

particle distribution can be adjusted through techniques such as milling and classification. These

processes can be tailored to meet the specific requirements of different end - users.These processes

can be tailored according to the needs of different end-users. Overall, while the general range of

0.5 - 5 microns is common, the precise particle size distribution of Kaolin BRITEX - 107 should be

determined through laboratory analysis, such as laser diffraction particle size analysis, to

accurately assess its suitability for a particular application.While the range of 0.5 - 5.0 microns

is a common one, the precise particle distribution of Kaolin BRITEX - 107 must be determined by

laboratory analysis such as laser diffraction to accurately assess the suitability of the product

for a specific application.

What are the main applications of Kaolin BRITEX-107?

Kaolin BRITEX - 107 has several main applications across different industries.Kaolin

BRITEX - 107 is used in a variety of industries.

In the paper industry, it plays a crucial role.In the paper industry it is a key ingredient. Kaolin

BRITEX - 107 is used as a coating pigment.Kaolin BRITEX - 107 can be used as a pigment for coatings.

When added to paper coatings, it improves the paper's surface smoothness.It improves the smoothness

of paper surfaces when added to paper coatings. This enhanced smoothness is beneficial for high -

quality printing as it allows for better ink absorption and transfer, resulting in sharper images

and more vivid colors.This improved smoothness is good for high-quality printing, as it allows

better ink transfer and absorption. The result is sharper images and vivid colors. It also helps in

increasing the brightness and opacity of the paper.It also increases the brightness and opacity.

Brightness makes the paper more visually appealing, while opacity prevents show - through of printed

content from the other side of the page, which is important for multi - page documents and

magazines.Brightness makes paper more appealing visually, while opacity helps prevent the

show-through of printed content on the other side of a page. This is important for magazines and

multi-page documents.

The paint and coating industry also benefits from Kaolin BRITEX - 107.Kaolin BRITEX 107 is also used

in the paint and coatings industry. It can be used as a filler.It can be used to fill. As a filler,

it helps to reduce the cost of paint formulations without significantly sacrificing the

performance.It can be used as a filler to reduce the price of paint formulations, without

compromising performance. It also improves the paint's rheological properties, such as its flow and

leveling.It also improves rheological characteristics of the paint, such as flow and leveling. This

ensures an even application of the paint on various surfaces.This ensures that the paint is applied

evenly on all surfaces. Additionally, it contributes to the paint's durability by enhancing its

resistance to abrasion and weathering.It also increases the paint's durability, as it is more

resistant to abrasions and weathering. In exterior paints, this property is especially important as

it helps the paint to withstand environmental factors like sunlight, rain, and wind for longer

periods.This property is particularly important in exterior paints as it helps to make the paint

more resistant to environmental factors such as sunlight, rain and wind.

In the plastics industry, Kaolin BRITEX - 107 can be incorporated as a filler.Kaolin BRITEX - 107 is

a filler that can be used in the plastics industry. It improves the mechanical properties of

plastics.It improves mechanical properties in plastics. For example, it can increase the stiffness

and strength of plastic products.It can, for example, increase the stiffness and durability of

plastic products. This is useful in applications where the plastic needs to maintain its shape under

stress, such as in automotive parts or plastic furniture.This is especially useful for applications

where plastics need to maintain their shape under stress. For example, automotive parts or plastic

furniture. It can also enhance the dimensional stability of plastics, reducing the tendency for

warping or shrinking during the manufacturing process and over time.It can also improve the

dimensional stability, reducing the tendency of plastics to warp or shrink during the manufacturing

process.

In the rubber industry, Kaolin BRITEX - 107 can be used as a reinforcing agent.Kaolin BRITEX - 107

is a reinforcing material that can be used in the rubber industry. It helps to improve the tensile

strength and tear resistance of rubber products.It improves the tensile and tear resistance of

rubber. This is valuable for items like tires, conveyor belts, and seals.This is useful for rubber

products such as tires, conveyor belts and seals. In tires, for instance, the addition of this

kaolin can enhance the tire's durability and performance, contributing to a longer lifespan and

better grip on the road.This kaolin, when added to tires, can improve their durability and

performance. This will lead to a longer tire life and better grip.

Overall, Kaolin BRITEX - 107 is a versatile material with applications that span multiple

industries, contributing to the improvement of product quality and performance in each of

them.Overall, Kaolin BRITEX - 107 has applications in multiple industries and contributes to the

improvement of quality and performance of products in each one.

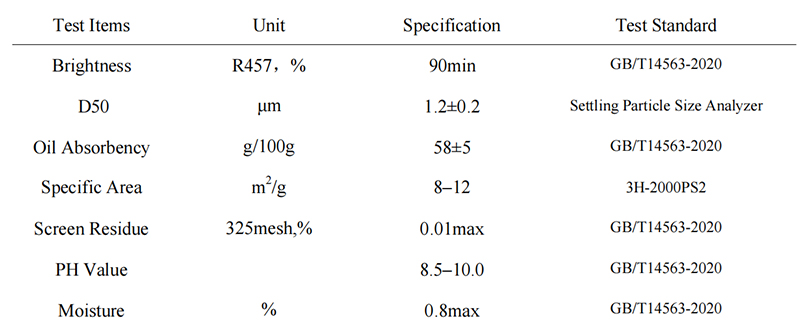

What is the moisture content of Kaolin BRITEX-107?

To accurately determine the moisture content of Kaolin BRITEX - 107, specific

laboratory testing is required.Specific laboratory testing is needed to accurately determine the

moisture contents of Kaolin BRITEX 107. The moisture content can vary depending on various factors

such as the source of the kaolin, its processing, storage conditions, and environmental

exposure.Moisture content can vary depending upon various factors, such as the kaolin's source, its

processing, the storage conditions and the environmental exposure.

Typically, kaolin is a clay mineral, and its moisture content can range significantly.Kaolin is a

clay-like mineral and its moisture content varies widely. In general, freshly mined kaolin may have

a relatively high moisture content, potentially in the range of 20 - 30% or even higher in some

cases, especially if it has been in contact with water - rich environments in the ground.Freshly

mined kaolin can have a high moisture content. It could be as high as 20-30% or even more in some

cases.

However, for commercial products like Kaolin BRITEX - 107, the manufacturer usually undertakes

processes to reduce the moisture content to a more stable and market - acceptable level.For

commercial products such as Kaolin BRITEX - 107 the manufacturer will usually reduce the moisture

content in order to reach a level that is more stable and acceptable to the market. This could

involve drying processes.This may involve drying processes. After proper drying, the moisture

content of kaolin products for industrial use might be in the range of 1 - 5%.After drying, the

moisture level of kaolin for industrial use could be between 1 and 5%. For applications where very

low moisture is crucial, such as in certain high - end ceramic or paper - coating applications, the

moisture content could be even lower, perhaps around 0.5 - 1%.If very low moisture content is

required, as in high-end ceramic or paper-coating applications, the moisture level could be even

lower. It may be around 0.5 to 1%.

Without access to the actual product data sheet from the manufacturer of Kaolin BRITEX - 107 or

conducting on - site moisture - content analysis using methods like oven - drying (where a sample is

heated to a specific temperature until a constant weight is achieved, and the weight loss is

attributed to moisture), it's impossible to give an exact value.It is impossible to provide an exact

value without access to the product data sheet of Kaolin BRITEX 107 from the manufacturer or

conducting on-site moisture - content analyses using methods such as oven - drying.

If the kaolin has been stored in a humid environment for an extended period, its moisture content

may increase.If kaolin is stored in a moist environment for a long time, the moisture content can

increase. On the other hand, if it has been stored in a dry and well - ventilated area, the moisture

content is likely to remain close to the value at which it was initially processed.If it is stored

in a well-ventilated, dry area, its moisture content will likely remain close to what it was when it

was first processed. So, while we can't provide a definite moisture content for Kaolin BRITEX - 107

without further information, understanding these general trends and factors influencing moisture

content can help in making an educated estimate or in interpreting future test results.While we

cannot provide a definite value for the moisture content of Kaolin BRITEX 107 without more

information, understanding the general trends and factors affecting moisture content can assist in

making an educated estimation or in interpreting any future test results.

What is the chemical composition of Kaolin BRITEX-107?

Kaolin BRITEX - 107 is a type of kaolin product.Kaolin BRITEX - 107 belongs to the

kaolin group. Kaolin is a clay mineral, mainly composed of kaolinite group minerals.Kaolin is a

clay, mainly composed by kaolinite group mineral.

The primary chemical components of Kaolin BRITEX - 107 typically include the following:The main

chemical components of Kaolin BRITEX - 107 are typically:

1. Silicon dioxide (SiO2): It is one of the major components.One of the main components is silicon

dioxide (SiO2). In kaolin, silicon atoms are part of the tetrahedral structure of the clay mineral

lattice.In kaolin silicon atoms form part of the tetrahedral lattice of the clay mineral. SiO2

content in kaolin usually ranges around 40 - 50% in general kaolin materials, and in Kaolin BRITEX -

107, it likely contributes significantly to the overall structure and properties.In general, the

SiO2 content of kaolin ranges between 40 - 50 %. In Kaolin BRITEX 107, this likely contributes to

its overall structure and properties. It provides a framework for the clay's physical

characteristics such as particle shape and texture.It is a foundation for the clay's properties,

such as its particle shape and texture.

2. Aluminum oxide (Al2O3): Another key component.Aluminum oxide (Al2O3) is another key component.

Aluminum is present in the octahedral layers of the kaolinite structure.Aluminum is found in the

octahedral layer of the kaolinite. Al2O3 content often accounts for approximately 30 - 40% in

kaolin.Al2O3 is often found in kaolin at a level of 30 - 40 %. In Kaolin BRITEX - 107, it plays a

crucial role in determining the clay's chemical reactivity, plasticity, and refractory properties.It

is a key component in Kaolin BRITEX-107 and determines the clay's chemical reaction, plasticity, as

well as its refractory properties. The aluminum - containing layers interact with other components

in the clay matrix.The aluminum-containing layers interact with the other components of the clay

matrix.

3. Water (H2O): Kaolin contains water in its structure.Water (H2O). Kaolin contains H2O in its

structure. There is both structural water and adsorbed water.Both structural water and adsorbed

(adsorbed) water exist. Structural water is an integral part of the kaolinite mineral structure and

is released at relatively high temperatures.Structural Water is a part of the mineral structure of

kaolinite and is released when temperatures are high. Adsorbed water is on the surface of the clay

particles and can be removed at lower temperatures.Adsorbed moisture is found on the surface of clay

particles, and can be removed by lowering the temperature. The water content can affect the clay's

plasticity, flowability, and overall physical state.The clay's plasticity and flowability can be

affected by the water content. In Kaolin BRITEX - 107, the water content needs to be controlled

within a certain range to ensure consistent product performance.To ensure consistent performance,

the water content of Kaolin BRITEX - 107 must be kept within a specific range.

4. Trace elements: Kaolin may also contain small amounts of other elements such as iron (Fe),

titanium (Ti), potassium (K), sodium (Na), and calcium (Ca).Kaolin can also contain trace amounts of

other elements, such as iron (Fe), Titanium (Ti), Potassium (K), Sodium (Na), or Calcium (Ca). Iron

and titanium impurities can affect the color of the kaolin, often causing it to have a yellowish or

brownish tint if present in relatively high amounts.Iron and titanium impurities may cause the

kaolin to appear yellowish or brownish if they are present in high quantities. In Kaolin BRITEX -

107, efforts are usually made to keep these trace element contents low to maintain a high - quality,

white - colored product, which is important for applications such as paper coating, ceramics, and

cosmetics.In Kaolin BRITEX - 107 it is important to keep trace element levels low in order to

maintain a white-colored product of high-quality for applications like paper coating, ceramics and

cosmetics.