What is the composition of Kaolin Monl Fil?

Kaolin is a type of clay mineral that is widely used in various industries.Kaolin is a

clay mineral widely used in many industries. However, "Kaolin Monl Fil" is not a commonly recognized

standard term.However, "Kaolin monl fil" is not a standard term. It might be a very specific product

name within a particular company or context.It could be a very specific name for a product within a

certain company or context.

Typical kaolin mainly consists of the mineral kaolinite.Kaolin is a silicate mineral with the

chemical formula Al2Si2O5(OH)4. Kaolinite is a layered silicate mineral with the chemical formula

Al2Si2O5(OH)4.Kaolinite is an layered silicate mineral that has the chemical formula Al2Si2O5 (OH)4.

In its pure form, kaolin contains significant amounts of aluminum and silicon, along with oxygen and

hydrogen in the form of hydroxyl groups.In its pure form kaolin contains significant quantities of

aluminum and silica, as well as oxygen and hydrogen, in the form hydroxyl groups.

Besides kaolinite, natural kaolin deposits often contain other associated minerals.Natural kaolin

deposits contain many other minerals besides kaolinite. Quartz is a common impurity.Quartz is a

common impurety. It is a crystalline form of silicon dioxide (SiO2).It is a crystalline version of

silicon dioxide (SiO2). Feldspars may also be present.Feldspars can also be found. Feldspars are a

group of aluminum - silicate minerals containing potassium, sodium, or calcium.Feldspars, a group of

aluminum-silicate minerals, contain potassium, sodium or calcium. These impurities can affect the

properties of kaolin, such as its color, particle size distribution, and chemical reactivity.These

impurities can alter the properties of Kaolin, including its color, particle distribution, and

chemical reactivity.

Iron - bearing minerals are another possible component.Iron-bearing minerals are also a possible

component. Even small amounts of iron can significantly impact the color of kaolin, often giving it

a yellowish or reddish tint.Iron can have a significant impact on the color of kaolin. It can give

it a yellowish, reddish or orange tint. Titanium - bearing minerals like rutile or anatase may also

be found in some kaolin deposits.Some kaolin deposits may also contain titanium-bearing minerals

such as rutile and anatase. These can influence the optical properties of the kaolin, especially its

brightness and opacity.These minerals can affect the optical properties of kaolin.

If "Kaolin Monl Fil" is a processed kaolin product, it may have additional components added during

manufacturing.If "Kaolin monl Fil" is a kaolin processed product, it could have had additional

components added during the manufacturing process. For example, it could contain dispersants to

improve its flowability in liquid systems.It could, for example, contain dispersants that improve

its flowability in fluid systems. These are usually organic compounds that help keep the kaolin

particles evenly dispersed.These are usually organic substances that help to keep the kaolin

particle evenly dispersed. There could also be additives to enhance its performance in specific

applications, such as binders for use in paper coating to improve the adhesion of the kaolin layer

to the paper substrate.Additives can also be used to improve its performance for specific

applications.

In summary, while the core of kaolin - based products is kaolinite, the exact composition of "Kaolin

Monl Fil" would depend on the source of the kaolin, any purification or processing steps it has

undergone, and any additives incorporated for its intended use.The composition of "Kaolin Monl Fil",

while kaolinite is the main component of kaolin-based products, will depend on its source, the

purification and processing it has undergone, as well as any additives added for the intended use.

Without more specific information about this particular product, it's difficult to provide a more

detailed and precise composition analysis.It's hard to provide a more precise and detailed

composition analysis without more specific information.

What are the main applications of Kaolin Monl Fil?

Kaolin is a soft, white clay that has been used for centuries in a wide range of

applications due to its unique properties.Kaolin is a white, soft clay that has been used in many

applications for centuries due to its unique characteristics. These properties include its fine

particle size, chemical inertness, high whiteness, and good plasticity.These properties include fine

particle size, chemical neutrality, high whiteness and good plasticity.

One of the main applications of kaolin is in the paper industry.Kaolin is used in the paper

industry. Kaolin is used as a coating pigment to improve the brightness, smoothness, and

printability of paper.Kaolin is used to improve the brightness, smoothness and printability of

papers. When kaolin is applied to the surface of paper, it fills in the gaps between the fibers,

creating a smoother surface that allows for better ink absorption and more vivid printing.When

kaolin pigment is applied to paper, it fills the gaps between fibers. This creates a smoother

surface, which allows for better ink absorbtion and vivid printing. This is especially important for

high - quality printing applications such as magazines, brochures, and packaging materials.This is

important for high-quality printing applications like magazines, brochures and packaging materials.

In the ceramics industry, kaolin plays a crucial role.Kaolin is a key ingredient in the ceramics

industry. It is a key ingredient in the production of porcelain, china, and other fine ceramics.It

is used in the production porcelain, china and other fine ceramics. Kaolin provides plasticity to

the ceramic body, allowing it to be shaped easily.Kaolin gives the ceramic body plasticity, which

allows it to be easily shaped. During firing, it helps to maintain the shape of the ceramic piece

and contributes to its strength, whiteness, and translucency.During firing it helps maintain the

shape of ceramic pieces and contributes to their strength, whiteness and translucency. It also

reduces the shrinkage of the ceramic during the drying and firing processes, minimizing the risk of

cracking.It also reduces shrinkage during the drying and the firing processes. This minimizes the

risk of cracking.

Kaolin is also used in the paint and coatings industry.Paint and coatings are also made with kaolin.

It acts as a filler and extender pigment.It is used as a pigment extender and filler. As a filler,

it can reduce the cost of paint formulations without significantly sacrificing performance.It can be

used as a filler to reduce the cost of paint formulations, without compromising performance. It also

improves the hiding power, viscosity, and durability of the paint.It also increases the paint's

durability, viscosity and hiding power. Kaolin's fine particle size helps to create a smooth film

when the paint is applied, enhancing the overall appearance of the painted surface.The fine particle

size of Kaolin helps create a smooth, even film when paint is applied. This enhances the appearance

of the painted surface.

In the plastic industry, kaolin is used as a filler.Kaolin is used in the plastics industry as a

filler. It can improve the mechanical properties of plastics, such as stiffness, strength, and

dimensional stability.It can improve mechanical properties of plastics such as stiffness and

strength. Kaolin - filled plastics are often used in applications where these properties are

important, such as in automotive parts, construction materials, and consumer goods.Plastics filled

with kaolin are used in many applications where these properties matter, such as automotive parts,

consumer goods, and construction materials.

Furthermore, kaolin has applications in the cosmetics and personal care industry.Kaolin is also used

in the cosmetics industry and in personal care products. Its fine texture and absorbent properties

make it suitable for use in products like face masks, powders, and foundations.Its fine texture,

absorbent properties, and versatility make it a good choice for products such as face masks and

powders. It can help to absorb excess oil on the skin, giving a matte finish, and its gentle nature

makes it suitable for most skin types.It can absorb excess oil from the skin and give it a matte

finish. Its gentle nature makes this product suitable for all skin types.

In addition, kaolin is used in the rubber industry.Kaolin is also used in the rubber sector. It

serves as a reinforcing filler, enhancing the mechanical properties of rubber compounds, such as

tensile strength and abrasion resistance.It is used as a filler to reinforce rubber compounds. This

increases their mechanical properties, such as their tensile strength, and abrasion resistant. This

is beneficial for products like tires, conveyor belts, and seals, where durability is essential.This

is especially useful for products such as tires, conveyor belts and seals where durability is a

must.

What are the advantages of Kaolin Monl Fil compared to other similar products?

Kaolin Monl Fil likely has several advantages over other similar products.Kaolin Monl

Fil has several advantages over similar products.

One of the key advantages might be its purity.One of its key advantages could be its purity. High -

purity kaolin used in Monl Fil can result in a product with fewer impurities that could potentially

affect its performance.Monl Fil, which uses high-purity kaolin, can produce a product that has fewer

impurities. This purity can lead to more consistent quality.This purity can result in a more

consistent product. In applications where product consistency is crucial, such as in the production

of high - end paper or certain types of ceramics, the consistent purity of Kaolin Monl Fil ensures

that each batch performs similarly, reducing the risk of defects or inconsistent results during

manufacturing processes.Kaolin Monl fil's consistent purity is ideal for applications that require

product consistency, such as the production of high-end paper or certain types ceramics.

Another advantage could be its particle size distribution.A third advantage is its particle size

distribution. If Kaolin Monl Fil has a well - controlled and optimized particle size, it can offer

better functionality.Kaolin Monl fil with a well-controlled and optimized particle size can offer

better functionality. For example, in coatings, smaller and more uniformly sized particles can

provide a smoother finish.In coatings, for example, smaller, more uniformly-sized particles can

produce a smoother surface. In the case of use in plastics as a filler, the appropriate particle

size can enhance the mechanical properties of the plastic, such as improving its stiffness without

sacrificing too much of its flexibility.When used as a plastic filler, the right particle size can

improve the mechanical properties of plastics, such as increasing their stiffness without

sacrificing much of their flexibility. This tailored particle size distribution gives it an edge

over competitors with less - controlled particle characteristics.This customized particle size

distribution gives them an edge over competitors who have less-controlled particle characteristics.

Kaolin Monl Fil may also have superior chemical stability.Kaolin Monl Fil also has a superior

chemical stability. This stability means it is less likely to react with other substances in the

environment or during processing.This stability means that it is less likely than other substances

to react in the environment or when processing. In applications where exposure to various chemicals

or environmental conditions is common, like in the construction industry when used in cement - based

products, its chemical stability ensures that it maintains its integrity over time.Chemical

stability is important in applications that are exposed to a variety of chemicals or environmental

conditions, such as in the construction industry, where cement-based products are used. It won't

break down or cause unwanted chemical reactions that could weaken the final product.It won't cause

unwanted chemical reactions or break down.

In addition, it might offer better rheological properties.It may also have better rheological

characteristics. Rheology refers to how a material flows and deforms under stress.Rheology is the

way a material flows or deforms when stressed. In products like paints and adhesives, proper

rheological properties are essential.Proper rheological characteristics are important in products

such as paints and adhesives. Kaolin Monl Fil with optimized rheology can help control the flow of

these products during application, ensuring an even spread and better adhesion.Kaolin Monl Fil that

has an optimized rheology will help control the flow during application of these products, ensuring

a better adhesion and even spread. This can result in a higher - quality end - product compared to

similar products that struggle with achieving the right flow characteristics.This can lead to a

higher-quality end-product compared to products that struggle to achieve the right flow

characteristics.

Finally, the sourcing and production process of Kaolin Monl Fil may be more sustainable.Finaly, the

production and sourcing of Kaolin Monl Fil could be more sustainable. In an era where environmental

concerns are increasingly important, a product that can be sourced and manufactured with less

environmental impact can be a significant advantage.In an age where environmental concerns are

becoming more important, a product which can be sourced or manufactured with a lower environmental

impact can be of great benefit. If the kaolin is mined using environmentally friendly practices and

the production of Monl Fil involves energy - efficient processes and reduced waste, it can appeal to

consumers and industries that prioritize sustainability.Monl Fil can be appealing to industries and

consumers who prioritize sustainability if the kaolin has been mined with environmentally friendly

practices, and the production process uses energy-efficient processes and reduces waste.

How is Kaolin Monl Fil processed and manufactured?

Kaolin Monl Fil is likely a specific form or grade of kaolin - a clay mineral.Kaolin

Monl Fil could be a specific grade or form of kaolin, a clay mineral. Here is a general overview of

how kaolin - based products like it may be processed and manufactured.Here's a general overview on

how kaolin-based products such as it are processed and manufactured.

The first step in kaolin processing is mining.Mining is the first step in kaolin production. Kaolin

is typically mined from open - pit mines.Open-pit mines are the most common place to mine kaolin.

The mined kaolin ore contains impurities such as sand, mica, and iron - bearing minerals.The kaolin

ore is contaminated with impurities like sand, mica and iron-bearing minerals. After mining, the ore

is transported to the processing plant.After mining, ore is transported to a processing plant.

At the plant, the initial step is beneficiation.Beneficiation is the first step in the plant. This

often begins with crushing and grinding.Crushing and grinding are usually the first steps. The large

chunks of kaolin ore are crushed into smaller pieces and then ground to a fine powder.The large

chunks are broken down into smaller pieces, and then ground into a fine powder. This increases the

surface area of the kaolin particles, making it easier to separate impurities.This increases the

surface of the kaolin particle, making it easier for impurities to be separated.

Next, the kaolin is usually subjected to a process called wet - processing.The kaolin will then be

subjected to wet-processing. In wet - processing, the ground kaolin is mixed with water to form a

slurry.In wet-processing, the ground kaolin and water are mixed to form a slurry. This slurry is

then passed through a series of separation steps.This slurry then goes through a series separation

steps. One common separation method is sedimentation.Sedimentation is a common separation method.

Larger, heavier impurities settle to the bottom of the tank, while the finer kaolin particles remain

in suspension.The heavier, larger impurities settle at the bottom of the tank while the finer

particles of kaolin remain in suspension.

Another important separation technique is flotation.Flotation is another important separation

technique. Chemicals are added to the slurry to selectively attach to the impurities.Chemicals are

added into the slurry in order to selectively attach the impurities. These impurities then rise to

the surface as froth, which can be skimmed off, leaving behind a cleaner kaolin slurry.These

impurities rise to the top as froth and can be skimmed away, leaving a cleaner kaolin. Magnetic

separation may also be used to remove iron - based impurities if present, as iron is magnetic.If

iron-based impurities are present, magnetic separation can be used to remove them.

After separation, the purified kaolin slurry may be further processed to adjust its particle size

distribution.After separation, the purified Kaolin slurry can be further processed to adjust

particle size distribution. This can be done through methods like classification, where the slurry

is passed through devices that separate particles based on their size.This can be achieved by using

methods such as classification, in which the slurry passes through devices that separate particles

according to their size. For products like Kaolin Monl Fil, achieving a specific particle size range

might be crucial for its end - use properties.For products such as Kaolin Monl Fil achieving a

certain particle size range could be crucial to its end-use properties.

The final step often involves dewatering and drying.Dewatering and drying are often the final steps.

The water is removed from the kaolin slurry through processes such as filtration or

centrifugation.Water is removed from kaolin slurry using centrifugation or filtration. The dewatered

kaolin is then dried, usually in a rotary dryer or a flash dryer.The dewatered material is then

dried in a rotary or flash dryer. After drying, the kaolin may be milled again to achieve the

desired final particle size and consistency.After drying, kaolin can be milled to obtain the desired

particle size and consistency.

Finally, quality control checks are carried out to ensure that the Kaolin Monl Fil meets the

required specifications in terms of purity, particle size, brightness, and other relevant properties

before it is packaged and shipped for various applications, which could include use in the paper,

ceramics, paint, or plastics industries.The Kaolin Monl Fil is then checked for purity, particle

size and brightness, as well as other relevant properties, before it is packaged up and shipped to

various industries, such as the paper, ceramics and paint industries.

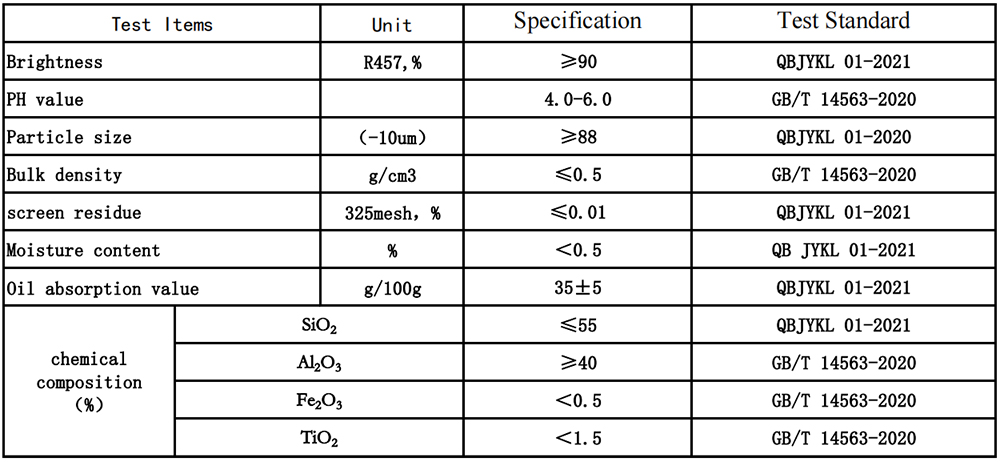

What is the quality standard of Kaolin Monl Fil?

Kaolin Monl Fil likely refers to a specific grade or type of kaolin product, perhaps

with "Monl Fil" denoting certain processing or application - specific characteristics.Kaolin Monl

Fil is likely to refer to a specific type or grade of kaolin, with "Monl Fil", perhaps denoting a

certain processing or application. Specific characteristics.

The quality standards for kaolin Monl Fil generally cover several aspects.The standards for kaolin

Monl Fil cover a wide range of aspects. One key aspect is chemical composition.Chemical composition

is one of the most important aspects. High - quality kaolin typically has a high content of alumina

(Al2O3) and silica (SiO2), with low levels of impurities such as iron oxide (Fe2O3), titanium

dioxide (TiO2), and other metal oxides.High-quality kaolin is typically composed of silica and

alumina, with low levels impurities like iron oxide (Fe2O3) or titanium dioxide (TiO2). Iron and

titanium oxides can affect the color and brightness of the kaolin, so for applications where

whiteness is crucial, like in the paper, paint, and ceramic industries, the levels of these

impurities need to be strictly controlled.Iron oxides and titanium dioxides can affect kaolin's

color and brightness. For applications where whiteness is important, such as in the paper, ceramics,

and paint industries, these impurities must be strictly controlled.

Particle size distribution is another important quality parameter.The particle size distribution is

also an important quality parameter. The fineness of kaolin particles can impact its performance in

different applications.The fineness of the kaolin particles will affect its performance for

different applications. In papermaking, finer - grained kaolin is often preferred as it can provide

better coating smoothness and ink receptivity.In papermaking, finer-grained kaolin can be preferred

because it can provide a better coating smoothness and improved ink receptivity. A narrow particle

size distribution may also be desired to ensure consistent product performance.To ensure consistency

in product performance, a narrow particle size distribution is often desired. Usually, the particle

size is measured using techniques like laser diffraction, and values are reported in terms of median

particle size (d50) and other distribution parameters.The particle size is usually measured using

laser diffraction techniques, and the values are reported as median particle size (d50), and other

distribution parameters.

Brightness and color are highly significant for many applications.Brightness and color play a major

role in many applications. Kaolin is expected to have a high brightness value, usually measured on a

scale such as the Hunter or ISO brightness scale.Kaolin should have a high level of brightness,

which is usually measured using a scale like the ISO or Hunter brightness scale. High - brightness

kaolin is essential for products like white - coated papers, where it enhances the visual

appeal.High - brightness Kaolin is essential for white-coated papers where it enhances visual

appeal. The color should be as white as possible, free from any tints or discolorations caused by

impurities.The color should be as pure as possible and free of any tints or discolorations due to

impurities.

The physical properties such as bulk density, plasticity, and rheological behavior are also part of

the quality standards.Quality standards also include physical properties like bulk density,

plasticity and rheological behaviour. In the ceramic industry, the plasticity of kaolin is crucial

as it determines how well the clay can be shaped.In the ceramics industry, kaolin's plasticity is

important because it determines the clay's ability to be shaped. In applications where kaolin is

used in a slurry form, like in some coating processes, its rheological properties, including

viscosity and flow characteristics, need to meet specific requirements to ensure proper application

and performance.In applications where kaolin in a slurry is used, such as in some coating processes

its rheological characteristics, including viscosity, must meet specific requirements in order to

ensure proper performance and application.

For certain industries, additional quality aspects may include surface chemistry.Surface chemistry

may be a quality aspect that is relevant to certain industries. For example, in polymer - filler

applications, the surface of the kaolin particles may need to be modified to improve compatibility

with the polymer matrix, which affects the mechanical properties of the final composite material.In

polymer-filler applications, for example, the surface of kaolin particles can be modified to improve

compatibility. This affects the mechanical characteristics of the final composite materials.