What is the main application of Kaolin HP-CC?

Kaolin HP - CC likely refers to a specific grade or type of kaolin with certain

characteristics.Kaolin HP-CC is likely to refer to a particular grade or type of clay with certain

characteristics. Kaolin in general has a wide range of applications, and the HP - CC variant may

have some specialized uses within these broader categories.Kaolin has a variety of uses, and the HP

– CC variant could have some specialized applications within these broader categories.

One of the main applications of Kaolin HP - CC is in the paper industry.Kaolin HP-CC is used in the

paper industry. In papermaking, kaolin is used as a coating pigment.In papermaking, Kaolin is used

to coat the paper. It helps to improve the smoothness, brightness, and printability of paper.It

improves the smoothness, brightness and printability of papers. The fine particle size and uniform

morphology of Kaolin HP - CC can fill the gaps between paper fibers, creating a more even

surface.Kaolin HP-CC's fine particle size and uniform morphology can fill in the gaps between paper

fibres, creating an even surface. This results in better ink absorption and sharper image

reproduction when the paper is printed.This leads to better ink absorption, and sharper images when

the paper is being printed. For high - quality printing papers like those used in magazines,

brochures, and art books, the use of kaolin in the coating formulation is crucial.The use of kaolin

is essential for high-quality printing papers, such as those used in art books, magazines, and

brochures.

In the ceramics industry, Kaolin HP - CC also plays an important role.Kaolin HP - CC plays a

significant role in the ceramics industry. Kaolin is a key raw material for making ceramics.Kaolin

is an important raw material in the production of ceramics. Its plasticity allows it to be easily

shaped into various ceramic products such as tiles, pottery, and porcelain.Its plasticity makes it

easy to shape into ceramic products like tiles, pottery and porcelain. The HP - CC type may be

particularly suitable for producing high - end ceramic items due to its purity and specific physical

properties.Due to its purity and physical properties, the HP-CC type is particularly suitable for

high-end ceramic products. It can enhance the strength, whiteness, and thermal stability of the

ceramics.It can improve the strength, whiteness and thermal stability of ceramics. For example, in

the production of fine porcelain, the use of high - quality kaolin like HP - CC helps to achieve a

delicate texture and a beautiful, translucent appearance.In the production of fine ceramics, for

example, the use high-quality kaolin such as HP-CC helps to achieve a delicate, translucent texture.

The paint and coatings industry is another area where Kaolin HP - CC can be applied.Kaolin HP – CC

is also used in the paint and coatings industries. It is used as a filler in paints.It is used in

paints as a filler. Kaolin can improve the viscosity, thixotropy, and hiding power of the

paint.Kaolin can increase the viscosity of paints, their thixotropy and their hiding power. By

adding Kaolin HP - CC, the paint can better cover the surface to be painted, reducing the amount of

pigment required.By adding Kaolin HP-CC to the paint, it can better cover the surface that needs to

be painted and reduce the amount of pigment needed. Additionally, it can enhance the durability and

weather resistance of the paint film, making it suitable for both interior and exterior

applications.It can also improve the durability and weather resistance, making the paint film

suitable for both exterior and interior applications.

In the rubber industry, kaolin can be used as a filler to improve the mechanical properties of

rubber products.Kaolin can be used in the rubber industry as a filler. This will improve the

mechanical properties. Kaolin HP - CC may be beneficial in providing better reinforcement,

increasing the tensile strength, tear resistance, and abrasion resistance of rubber.Kaolin HP-CC can

be used to improve rubber's tensile strength and tear resistance. This makes it useful in the

production of tires, conveyor belts, and other rubber - based industrial products.This makes it

useful for the production of rubber-based industrial products such as tires, conveyor belts and

other rubber-based industrial products.

What are the key properties of Kaolin HP-CC?

Kaolin HP - CC likely has several key properties.Kaolin HP - CC is likely to have

several key properties.

First, in terms of its physical properties, it typically has a fine particle size.It is

characterized by a fine particle size. This fine - grained nature gives it a smooth texture, which

is beneficial in applications where a homogeneous and even finish is required.This fine-grained

texture gives it a smooth finish, which is useful in applications that require a homogeneous, even

finish. For example, in the production of high - quality papers, the fine particles can fill in the

gaps between paper fibers, resulting in a smoother paper surface that is better for printing and

writing.Fine particles can be used to fill in the gaps in paper fibers in high-quality papers. This

results in a smoother surface for printing and writing.

Secondly, it has good whiteness.Second, it is very white. High whiteness makes it an ideal additive

in industries such as the paint and coating industry.Its high whiteness makes it a perfect additive

for industries like the paint and coatings industry. In paints, the white kaolin can enhance the

brightness and opacity of the final product.The white kaolin in paints can increase the brightness

and opacity. This property also makes it valuable in the plastic industry, where it can be used to

improve the appearance of plastic products, especially in applications where a light - colored or

white plastic is desired.This property makes it useful in the plastics industry, where it is used to

improve the look of plastic products.

Kaolin HP - CC also has excellent chemical stability.Kaolin HP - CC has also excellent chemical

stability. It is relatively inert and does not react easily with most common chemicals.It is

relatively inert, and does not react with most common chemicals. This stability allows it to be used

in various formulations without causing unwanted chemical reactions.Its stability allows it be used

in a variety of formulations without causing unwanted reactions. For instance, in ceramic

manufacturing, it can withstand high - temperature firing processes without decomposing or reacting

with other ceramic components, thus helping to maintain the integrity and quality of the ceramic

products.It can be used in ceramic manufacturing to resist high-temperature firing processes without

decomposing and reacting with other ceramic materials.

Another important property is its colloidal properties.Colloidal properties are another important

property. It can form stable suspensions in water.It can form stable suspensions when dissolved in

water. This is useful in the paper - making process, as it enables the even distribution of kaolin

particles within the paper pulp slurry.This is helpful in the paper-making process, because it

allows for an even distribution of kaolin within the pulp slurry. In addition, in some cosmetic

applications, its ability to form suspensions can help in formulating products like face masks or

creams, ensuring that the kaolin is uniformly dispersed throughout the product.In cosmetics, the

ability to form suspensions is useful in formulating products such as face masks and creams. This

ensures that the kaolin particles are evenly distributed throughout the product.

Finally, it has a certain degree of plasticity.It also has a certain amount of plasticity. In the

ceramic industry, this plasticity allows the shaping of ceramic bodies.This plasticity is used in

the ceramic industry to shape ceramic bodies. Potters can mold the kaolin - containing clay into

various forms, and the plasticity helps the clay maintain its shape during the initial stages of

production before firing.The clay containing kaolin can be molded into many different shapes by

potters, and its plasticity helps it to maintain its shape in the initial stages of production.

Overall, these properties make Kaolin HP - CC a versatile and valuable material across multiple

industries.These properties make Kaolin HP – CC a versatile material that is valuable in multiple

industries.

How is Kaolin HP-CC different from other types of kaolin?

Kaolin HP - CC likely has several differences compared to other types of kaolin.Kaolin

HP-CC is likely to have several differences from other types of kaolin.

First, in terms of purity.Purity is the first thing to consider. Some common kaolin may contain

various impurities like iron oxides, titanium dioxide, or other minerals.Some common kaolin can

contain impurities such as iron oxides or titanium dioxide. Kaolin HP - CC might be processed to

achieve a higher level of purity.Kaolin HP – CC can be processed in order to achieve a higher

purity. High - purity kaolin is often desired in applications where color and chemical reactivity

are crucial.In applications where color and chemical reaction are important, high-purity kaolin can

be desired. For example, in the production of high - quality paper, a purer kaolin like HP - CC can

provide better whiteness and opacity.In the production of high-quality paper, a more pure kaolin,

such as HP - CC, can provide better whiteness, opacity, and transparency. The reduced impurities

mean less interference with the optical properties of the final product.The reduced impurities will

have a less significant impact on the optical properties of final products.

Particle size and distribution also set it apart.The particle size and distribution are also

distinguishing features. Kaolin HP - CC may have a more uniform and precisely controlled particle

size.Kaolin HP-CC may have a more controlled and uniform particle size. In coatings, a narrow

particle size distribution can lead to better film - forming properties.A narrower particle size

distribution in coatings can result in better film-forming properties. Smaller and more consistent

particles can result in a smoother surface finish.A smoother surface can be achieved by using

smaller and more consistent particle sizes. This is different from some general - grade kaolins that

may have a wider range of particle sizes, which could lead to unevenness in applications such as

paints or plastics.This is different than some general-grade kaolins, which may have a larger range

of particle size, leading to unevenness in paints and plastics.

The surface chemistry of Kaolin HP - CC is another differentiator.Kaolin HP-CC also differs in its

surface chemistry. It may be chemically treated to modify its surface properties.Chemically, it can

be treated to change its surface properties. This can enhance its compatibility with different

polymers or solvents.This can improve its compatibility with polymers or solvents. For instance, in

the plastics industry, a kaolin with a modified surface can disperse more evenly within the polymer

matrix, improving the mechanical properties of the plastic composite.In the plastics industry for

example, a kaolin surface modified can disperse evenly within the matrix of polymer, improving the

mechanical properties. Other types of kaolin may not have such tailored surface treatments, limiting

their effectiveness in certain applications.Other types of Kaolin may not have the same tailored

surface treatments and therefore be less effective in certain applications.

In terms of applications, due to its unique properties, Kaolin HP - CC is likely targeted at high -

end markets.Kaolin HP – CC is likely to be targeted at high-end markets due to its unique

properties. It may be used in advanced ceramics, where its high purity and specific particle

characteristics contribute to better sintering behavior and improved mechanical and electrical

properties of the ceramic products.It can be used in advanced Ceramics where its high purity and

unique particle characteristics help improve sintering behaviour and mechanical and electrical

properties. In contrast, other kaolins might be more commonly used in lower - cost applications like

filler in construction materials, where the strict requirements for purity and particle properties

are not as high.Other kaolins may be used more frequently in applications with lower costs, such as

filler in construction material, where the requirements for purity and particle characteristics are

less strict. Overall, Kaolin HP - CC stands out through its purity, particle characteristics,

surface chemistry, and its suitability for more specialized and demanding applications.Kaolin HP –

CC is distinguished by its high purity, particle properties, surface chemistry and suitability for

specialized and demanding applications.

What are the advantages of using Kaolin HP-CC in various industries?

Kaolin HP - CC offers several advantages across various industries.Kaolin HP - CC has

many advantages in a variety of industries.

In the paper industry, one of the key benefits is its ability to improve paper quality.Kaolin HP -

CC has a fine particle size and uniform distribution. Kaolin HP - CC has fine particle size and

uniform distribution.Kaolin HP - CC is characterized by fine particles and uniform distribution.

When added to paper pulp, it helps in creating a smoother paper surface.It helps create a smoother

surface when added to paper pulp. This smoothness is crucial for high - quality printing as it

allows for better ink absorption and transfer, resulting in sharper images and clearer text.This

smoothness is essential for high-quality printing, as it allows better ink transfer and absorption,

resulting in sharper pictures and clearer text. It also enhances the brightness and opacity of the

paper.It also increases the brightness and opacity. By increasing opacity, less fiber is needed to

achieve the desired level of light - blocking, which can lead to cost savings in raw material

procurement while maintaining or improving the overall paper quality.The paper can be made more

opaque by increasing the opacity. This will reduce the amount of fiber required to achieve the

desired light-blocking.

In the paint and coating industry, Kaolin HP - CC serves as an excellent extender and functional

pigment.Kaolin HP – CC is a functional pigment and extender that is used in the paint and coatings

industry. It has good chemical stability, which means it does not react easily with other components

in the paint formulation.It is chemically stable, meaning it doesn't react with other components of

the paint formulation. This stability helps in maintaining the long - term integrity of the

paint.This stability helps to maintain the long-term integrity of the paint. Additionally, its fine

particle nature contributes to the viscosity control of the paint.Its fine particle size also

contributes to the control of paint viscosity. It can prevent settling of other pigments, ensuring a

homogeneous mixture.It can prevent other pigments from settling, ensuring a homogeneous mix. When

the paint is applied, Kaolin HP - CC improves the film - forming properties, enhancing the

durability and scratch - resistance of the coating.Kaolin HP – CC enhances the durability and

scratch resistance of the coating when it is applied. It also helps in reducing the gloss of the

paint if a matte finish is desired, providing more versatility in product offerings.It can also be

used to reduce the gloss of paints if a matte look is desired. This gives more versatility to

product offerings.

For the plastic industry, Kaolin HP - CC can be used as a filler.Kaolin HP-CC can be used in the

plastics industry as a filler. It has high hardness and abrasion resistance, which can enhance the

mechanical properties of plastics.It is abrasion resistant and has a high hardness, which can

improve the mechanical properties of plastics. When incorporated into plastic compounds, it can

increase the stiffness and strength of the plastic parts.It can be incorporated into plastic

compounds to increase the stiffness of the plastic parts. This is particularly useful in

applications where the plastic needs to withstand mechanical stress.This is especially useful in

applications where plastics need to be able to withstand mechanical stresses. Moreover, Kaolin HP -

CC can improve the dimensional stability of plastics.Kaolin HP – CC can also improve the dimensional

stability in plastics. It reduces the shrinkage that occurs during the cooling and solidification

process of plastic molding, ensuring that the final plastic products maintain their shape

accurately.It reduces shrinkage during the cooling and hardening process of plastic molds, ensuring

that final plastic products retain their shape.

In the ceramics industry, Kaolin HP - CC is a fundamental raw material.Kaolin HP – CC is a key raw

material in the ceramics industry. It has good plasticity, which allows ceramic products to be

easily shaped during the manufacturing process.It is a good plastic material, which makes it easy to

shape ceramic products during the manufacturing process. It also has a low firing shrinkage, meaning

that the ceramic items are less likely to crack or deform during the firing process.It has a low

shrinkage during firing, which means that ceramic products are less likely crack or deform. This

results in higher - quality ceramic products with better surface finish and fewer defects.This

results in ceramic products of higher quality with a better surface finish and less defects. The

unique chemical composition of Kaolin HP - CC also contributes to the glaze formation and color

development in ceramics, enabling the production of a wide variety of aesthetically pleasing ceramic

items.Kaolin HP CC's unique chemical composition also contributes to glaze formation and color

development, enabling a wide range of aesthetically pleasing ceramic products.

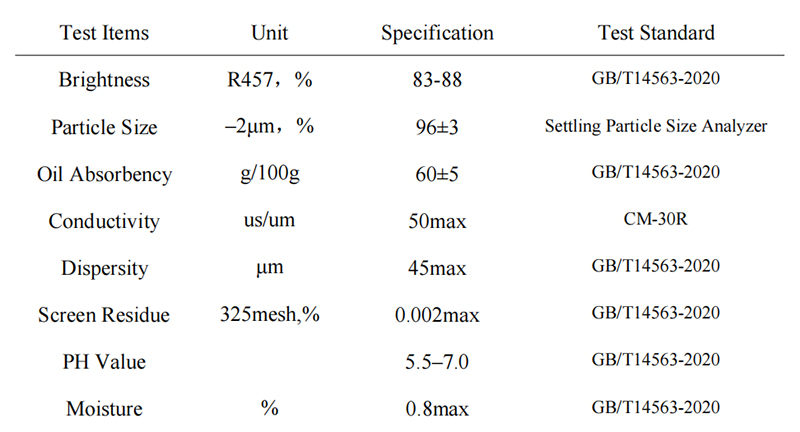

What are the typical specifications of Kaolin HP-CC?

Kaolin HP - CC likely refers to a high - performance grade of kaolin with specific

characteristics.Kaolin HP-CC is a high-performance grade of kaolin that has specific

characteristics. Here are some typical specifications:Here are some typical specs:

Particle SizeParticle Size

One of the key specifications is the particle size distribution.The particle size distribution is

one of the most important specifications. For high - performance kaolin like HP - CC, a fine

particle size is often desired.A fine particle size is desired for high-performance kaolins like HP

- CC. Commonly, a significant portion of the particles may have a diameter in the range of 1 - 2

microns.A significant portion of particles can have a diameter between 1 and 2 microns. A narrow

particle size distribution is also beneficial as it can contribute to better suspension properties

in various applications.A narrow particle distribution can also be beneficial, as it can improve the

suspension properties of various applications. For example, in coatings, a uniform particle size

helps in achieving a smooth and even film formation.In coatings, for example, a uniform size of

particles helps to achieve a smooth, even film.

Chemical CompositionChemical Composition

Kaolin is mainly composed of aluminum silicate minerals.Kaolin is composed primarily of aluminum

silicate minerals. The HP - CC grade usually has a high purity of kaolinite.The HP-CC grade is

usually a high purity kaolinite. The alumina (Al2O3) content is typically around 38 - 40%, while the

silica (SiO2) content is approximately 45 - 50%.The alumina content (Al2O3) is usually between 38

and 40%, while silica content (SiO2) is around 45 to 50%. Impurities such as iron oxide (Fe2O3),

titanium dioxide (TiO2), and alkali metal oxides should be present in very low amounts.Impurities

like iron oxide (Fe2O3) and titanium dioxide (TiO2) should be present at very low levels. Low iron

oxide content is crucial as it can cause discoloration, especially in applications where color

purity is important, like in paper coating and white pigments.Iron oxide content should be low, as

it can cause discoloration in applications that require color purity, such as paper coatings and

white pigments.

WhitenessWhiteness

High whiteness is a characteristic of HP - CC kaolin.HP - CC kaolin is characterized by its high

whiteness. It often has a brightness value, measured on the Hunter scale, of 90 or above.It has a

brightness rating of 90 or more on the Hunter scale. This high whiteness makes it suitable for

applications where a bright and clean appearance is required, such as in the production of high -

quality paper, plastics, and ceramics.This high whiteness is ideal for applications that require a

bright, clean appearance, such as the production of high-quality paper, plastics and ceramics. A

high - whiteness kaolin can enhance the visual appeal of the final product.High-whiteness kaolin can

improve the visual appeal of a final product.

Brightness StabilityBrightness Stability

In addition to initial high whiteness, the brightness stability of HP - CC kaolin is important.The

brightness stability of HP CC kaolin, in addition to its initial high whiteness is important. It

should maintain its whiteness over time, even when exposed to environmental factors or during

processing.It should retain its whiteness even after exposure to environmental factors or

processing. This is particularly relevant in applications where the product will be stored or used

for an extended period.This is especially important in applications where products will be stored

for a long time or used.

Surface AreaSurface Area

The surface area of HP - CC kaolin can vary, but it generally has a moderate to high surface area.HP

- CC kaolin has a surface area that can vary but is usually moderate to high. A higher surface area

can improve the interaction with other substances in a formulation.A higher surface area will

improve the interaction of other substances in a formula. For instance, in rubber applications, a

kaolin with an appropriate surface area can enhance the reinforcement effect, improving the

mechanical properties of the rubber.In rubber applications, for example, a kaolin that has a

suitable surface area can enhance reinforcement, improving the mechanical characteristics of the

rubber.

Oil AbsorptionOil Absorption

The oil absorption value of HP - CC kaolin is another specification.Another specification is the oil

absorption value. It can range from 30 - 50 g/100g.It can range between 30 -50 g/100g. This value is

relevant in applications like paints and inks, as it affects the viscosity and rheology of the

formulation.This value is important in paints and inks as it affects viscosity, rheology and the

formulation. A lower oil absorption can lead to a more fluid - like product, while a higher value

may result in a thicker consistency.A lower oil absorption value can result in a fluid-like product,

while a high value can result in a thicker consistency.